Better safe than sorry?

Is it necessary to wear PPE even when ‘just’ working with lower water pressure? Isn’t that just for cowards? Read this article first, and then we think you’ll have the answer.

It’s quite easy to grasp that ultra-high water pressure, which removes concrete, can be dangerous. But even at lower water pressures, you’re at risk for injuries. Our eyes can be damaged at a pressure of 7 bar/100 psi and above, while skin penetration may occur at 80 bar/1 160 psi and above. High-pressure cleaning uses approximately 200 bar/2 900 psi…

It’s not only the strength in the water jet that makes it dangerous. Wounds from a high-pressure water jet accident can often seem minor because they’re generally quite small. But the dirty water that penetrates the skin can be filled with bacteria and microorganisms, putting these injuries at high risk of serious infection, which could lead to discomfort, disability, and even amputation if not treated properly.

“HE WAS STUCK IN THE HOSPITAL BED FOR A WEEK BEFORE HE FINALLY COULD GO HOME”

– We have seen many examples of a small wound that need urgent medical care, due to the high risk of infection. We had one guy here in Sweden that slipped with his waterjet gun and got a small wound on his right foot. The doctors had to make a 15 cm long incision on each side of his leg in order to drain and clean the wound. He was stuck in the hospital bed for a week before he finally could go home, says Peder Lindström, Market & Sales Director at TST Sweden.

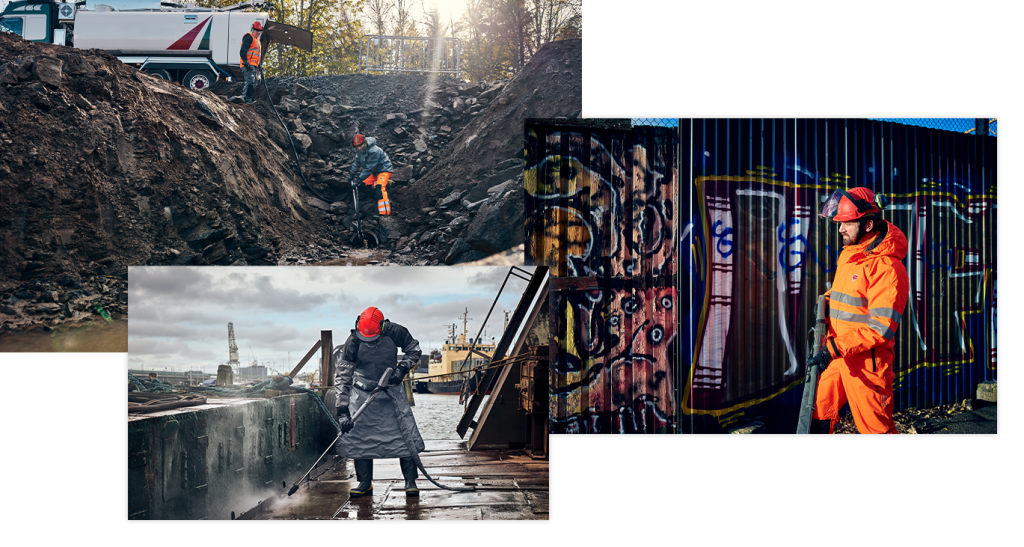

TST Sweden develops and manufactures protective clothing for ultra-high pressures as well as PPE for lower pressures. Our ProOperator range protects against water pressure up to 500 bar/ 7 500 psi and is frequently used by operators who for example remove graffiti, clean sludge, and work within marine services. Areas where some may think wearing PPE is unnecessary.

– The things we have encountered during our time in the business are nothing for the faint-hearted, but it has really made it clear how important PPE is even when working with low water pressure, says Peder Lindström.

Our mission is to ‘Save lives’ and a big part of that is making sure that as many operators as possible are wearing proper protection. To reach that goal we have been working closely with the end users to find out what will get them to put on proper PPE.

“WE ALL KNOW THAT ACCIDENTS HAPPEN. EVEN THE MOST EXPERIENCED OPERATOR CAN SLIP, HOSES BURST, AND COUPLING BREAKS”

– After many conversations with end users all over the world, it has become clear to us that the key element to PPE being used simply is comfort. If the clothing is comfortable to wear, the operators will use them, and they will stay safe. So simple, really. Therefore, we’ve put a lot of effort into making our clothing as comfortable and flexible as possible so that workers both can and want to wear them all day, says Peder Lindström.

A big part of our work towards creating comfortable PPE has been their fabric choice. The protective surface in Prooperator is made of Dyneema®, a fiber that is very light, yet 15 times stronger than steel. It’s the same strong fabric that are used in their PPE for waterjetting up to 3 000 bar / 43 500, but only one layer instead of three. In this way, ProOperator can protect up to 500 bar/7 500 psi, while the clothing is so comfortable that it can be worn all day.

The outer material is treated with DWR (Durable Water Repellent) treatment. This keeps the operator dryer and lighter, and makes the clothes easy to clean. All ProOperator clothes have waterproof zippers and/or overlapping flaps. Also, the ProOperator products have lot of smart details, like reinforced knees on trousers and overalls and the added pocket for knee pads, openable ventilation in the armpits and pocket for ID card.

The ProOperator range is also available in a high visibility version. The functionality and comfort are the same as the standard range in gray fabric. The only difference is the fluorescent orange color with added reflective material.

So, is it necessary to wear PPE even when ‘just’ working with lower water pressure?

– We all know that accidents happen. Even the most experienced operator can slip, hoses burst, and coupling breaks. If you aren’t properly protected and you’re exposed to that water pressure, there’s a high risk that you could suffer severe injuries, says Peder Lindström.

TST Sweden article published in WJTA Jet News, reprinted with permission.